A New Design for a Solar Dryer: PART II

Summary of PART I

In my previous article (part I), we discovered that agricultural products such as mangos, onions, bananas, grapes, tomatoes, and other vegetables are prone to spoilage. To prevent food spoilage, the use of solar drying systems becomes essential. Traditional outdoor drying methods are costly, labor-intensive, and expose food to damaging UV rays, leading to losses. Solar dryer systems, particularly modular hemispherical ones, offer an innovative solution by efficiently drying, heating, and controlling pests while preserving the food’s nutrients, aroma, flavor, and appearance. Moreover, the unique hemispherical design not only maximizes the internal drying chamber volume but also minimizes insulation requirements, making the system more efficient. As a result, solar dryer systems have significantly transformed the way we preserve food products. By utilizing renewable energy, they provide a sustainable and cost-effective alternative to traditional drying methods. Consequently, these advancements contribute to reducing food waste, improving food security, and promoting eco-friendly practices.

Users can operate the dryer in two modes: drying produce like pulses, dry fruits, and cereals, and implementing physical disinfection post-harvest, thanks to their low moisture content. Additionally, farmers increasingly utilize solar dryer systems, particularly for agricultural products with high water content, such as fresh fruits and vegetables. Notably, the innovative hemispherical shape plays a crucial role in enhancing efficiency. This unique design facilitates excellent air circulation, ensures precise temperature control, and enables effective humidity regulation. As a result, it becomes highly suitable for both indoor and outdoor settings, offering farmers greater flexibility and convenience.

In countries like India, where solar radiation levels range between 4 and 7 kWh/m2/day on sunny days, solar drying systems prove highly beneficial.

Solar Dryer Systems: Drying and Disinfection

Drying and disinfection are essential for improving shelf life after harvest. You can disinfect it without using pest control. Heat it to 55 to 60 degrees Celsius. Keep it at this temperature for at least 30 minutes. This can disinfect it. The promising option is to remove the moisture and reduce it up to 10 to 11%. During drying, the temperature can be increased up to the disinfection range with controlled air change. Using solar energy to dry agricultural products helps meet demand without waste. It does this in a sustainable way. With solar drying, its long-term preservation is a vital part.

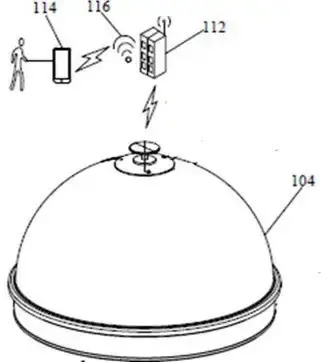

Temperature and duration of exposure can be controlled remotely by the IoT, as shown in Figure 1. Nomenclature: 104 Solar dryer systems, 114 User devise, 112 Controller, 116 Communication Media.

Figure 2 shows a photo of a modular solar dryer systems for domestic applications designed for a 1 kg load.

Working of dryer is in two modes first is during day which utilizes direct solar energy when available as shown in Fig.3. In second mode when solar radiations are not available either in night or off sunshine hours solar heat energy stored in hot water is used by using heat exchanger, blower, main duct and supply duct. All system components are well insulated as shown in Fig 4.

Working Solar Dryer Systems

The controller works with the humidity sensor and temperature sensor. Together, they manage how the blower motor works. This motor is part of the air change mechanism. The controller monitors time, temperature, and humidity inside the dryer and maps such parameters to the user device. The user device is set up to get real-time updates from the controller. These updates are about the drying process. They cover temperature, humidity, and how long the drying takes. In drying processes, changing the air is crucial. This innovative hemispherical design makes it possible. Hot and humid air ascends and accumulates at the top end of the dryer. The blower operates intermittently in this area. It turns on and off based on the dryer’s internal temperature and humidity. This makes it easy to remove moisture or particles.

EDUCATIONAL OPPORTUNITIES

Among the numerous applications of solar energy, drying stands out as a particularly promising area for research. Over the years, technological advancements have significantly improved this field, making solar drying more efficient and accessible. As a result, engineers now face the challenge of developing versatile models that not only enhance performance but also offer a user-friendly interface for ease of use.

Furthermore, students interested in this domain should focus on building a strong fundamental understanding of solar thermal energy applications. By doing so, they can explore solar energy as a viable career option and contribute to the ongoing development of innovative and sustainable drying technologies.

CAREER PATH

Solar dryer systems finds its place for agricultural, processing, and packaging researchers. All these domains of applications need clever marketing. The significant sector for this new design is domestic users.

CONCLUSION

Solar dryer systems, using enclosed structures and natural or forced airflow, is a good method. It helps reduce losses after harvest.Additionally, it improves the quality of dried products, unlike traditional sun-drying methods. The proposed design can be highly beneficial for both passive and active solar dryers.

This design serves two primary functions. First, it effectively dries the agricultural produce. Second, it protects the produce from direct sunlight, which helps maintain its nutritional value, smell, taste, and color. As a result, the final product remains more visually appealing and flavorful compared to traditional drying methods.

Furthermore, because the dryer is shaped like a hemisphere, air moves around and circulates evenly throughout the drying space. Consequently, this results in uniform drying, ensuring that all parts of the produce receive consistent exposure. Moreover, the air removal point is strategically positioned at the highest point, which significantly enhances the drying process. This placement not only facilitates efficient air removal but also minimizes unnecessary air exchange during disinfection, thereby improving the overall drying efficiency.

References

Raul Raudales. Aug2,2005 Vegetable Product Drying, U.S.Patent US6922908B1 https://patents.google.com/patent/US6922908B1/ en

Additionally, to stay updated with the latest developments in STEM research, visit ENTECH Online. Basically, this is our digital magazine for science, technology, engineering, and mathematics. Furthermore, at ENTECH Online, you’ll find a wealth of information.