Bamboo Molecular Plastics: Sustainable, Strong, and Biodegradable Future Materials

Breaking New Ground with Bamboo-Based Bioplastics

Plastic pollution poses a major threat to our environment, with less than 10% of plastics recycled globally. Traditional plastics, unlike biodegradable plastics, come from petrochemicals and can harm ecosystems as they break down into microplastics. To tackle this, scientists are focusing on sustainable alternatives. One exciting development is bamboo molecular plastics (BM-plastics), crafted from fast-growing bamboo fibers.

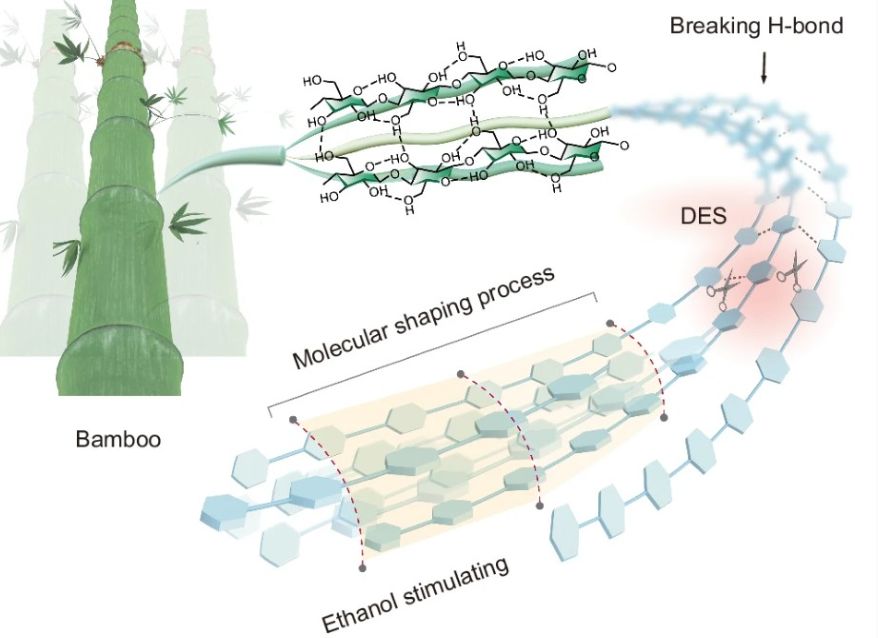

Researchers use a special solvent mixture made of hydrated zinc chloride and formic acid to dissolve bamboo cellulose at the molecular level. This step breaks down the natural hydrogen bonds in bamboo fibers to create biodegradable plastics from a uniform cellulose solution. Ethanol reorganizes the molecules after this. Thus, it forms strong hydrogen bonds that give the material excellent mechanical strength and moldability.

How is BM-Plastic Made?

The process starts by breaking apart the rigid structure of bamboo using a solvent to get cellulose molecules dispersed evenly. Next, adding ethanol leads to restructuring where molecules pack tightly together. The result is a tough yet flexible plastic that performs better than common commercial plastics like high-density polyethylene (HDPE) or polylactic acid (PLA). Additionally, this manufacturing happens at room temperature, reducing energy use compared to traditional plastic production methods that do not produce biodegradable plastics.

The Advantages of BM-Plastic

BM-plastics combine high tensile strength, thermal stability, and excellent recyclability, keeping 90% of their mechanical properties after recycling. They fully biodegrade in soil within just 50 days, which is far quicker than most petroleum-based plastics. This promotes circularity — meaning materials cycle through use and breakdown naturally without lasting pollution, a key feature of biodegradable plastics.

The Environmental and Industrial Impact

Bamboo grows rapidly and yields much more biomass per hectare than traditional trees, making it one of the most renewable resources for bioplastic production. The BM-plastic technology, therefore, supports sustainability goals while offering scalable manufacturing potential. In this context, the use of biodegradable plastics like BM-plastics marks significant progress in environmental conservation.

This new class of bio-based materials can be used in cars, construction panels, packaging, and electronics. The sectors are heavily reliant on conventional plastics today. By replacing fossil-derived plastics with BM-plastics, industries can significantly cut their carbon footprints while reducing overall waste accumulation from non-biodegradable plastics.

The Science Behind Superior Properties

X-ray diffraction tests have revealed that ethanol treatment converts the cellulose into highly ordered crystalline structures within BM-plastics. This structural change enhances strength without compromising flexibility. Meanwhile, microscopic images show fewer pores compared to similar bio-gels indicating denser material formation ideal for durable applications like those needed for biodegradable plastics.

Reference:

- Tang, H., Tong, Z., Zhang, R., Li, X., Zeng, S., Zhao, D., & Yu, H. (2025). High-strength, multi-mode processable bamboo molecular bioplastic enabled by solvent-shaping regulation. Nature Communications, 16(1). https://doi.org/10.1038/s41467-025-63904-2

Additionally, to stay updated with the latest developments in STEM research, visit ENTECH Online. Basically, this is our digital magazine for science, technology, engineering, and mathematics. Further, at ENTECH Online, you’ll find a wealth of information on innovations like biodegradable plastics.