Body-in-White Design Structure – An Overview for Curious Minds

Estimated reading time: 10 minutes

When you see a car in a showroom, what grabs your attention first? Maybe it’s those dazzling headlights, artistic curves, fancy wheels, or the glowing dashboard with tons of infotainment and features. Mostly, people — including every rookie engineer — start their automotive journey here, mesmerized by the stuff that can be experienced by our senses. But the real hero? It’s all hidden beneath the surface, a masterpiece of brilliant engineering, Body-in-White (BIW).

This unsung hero is the backbone, the indispensable framework that makes cars safe, comfortable, and reliable. Get ready for a journey that’ll connect your classroom equations to every ride you take!

What Exactly is the Body in White (BIW) Design?

The BIW is the complex structural framework of stamped metal panels, beams, reinforcements, and welded joints that form the foundation of the vehicle. It’s a hidden skeleton that largely decides whether a car will protect its occupants in a crash. It is the “safety shield” for passengers—and now for the battery pack too. When the unavoidable happens, the BIW is the last line of defense after all “active safety measures” fail to avoid the crash.

Key functions of the BIW:

- Crash Safety — It absorbs energy in crashes.

- Mounting — It holds the engine, battery, suspension, and systems in place.

- Comfort — Indeed, it controls vibration and noise, keeping passengers at ease.

- Rigidity — It resists bending and twisting during motion.

Also Read: Basics of Automobile Engineering.

A Global Call for Safer Vehicle Structures

The Onus is on BIW Design Structure

The World Health Organization (WHO) reports 1.19 million annual traffic fatalities worldwide and up to 50 million injuries each year. Side-intrusion crashes remain especially deadly, with 46,000 road deaths recorded in the U.S. alone in 2022. In India, the situation is even worse.

For Electric Vehicles, the stakes are even higher. With 69 million electric vehicles (EVs) now on the world’s roads in mid-2025, and annual EV sales racing toward 22 million units this year, the automotive landscape is witnessing a profound shift. Unlike an internal combustion engine (ICE) car, where the relatively small fuel tank can deform without catastrophic consequences, an EV’s massive battery pack (which often weighs around half a ton) sits under the floor and cannot tolerate intrusion. A punctured cell can trigger a thermal runaway event, turning a crash into a life-threatening fire for occupants and surroundings.

Also Read: Want to Build Safer Cars? Read this Engineer’s Story!

BIW Design: Why Should STEM Students Care?

When I was in school, I used to ponder: “Why force, energy, acceleration? What do these formulas matter when I just want to build something cool, not solve endless textbook problems?” Maybe some of you relate! Little did I know, those abstract concepts would become my daily tools. Every bit of physics, every equation forms the backbone of BIW decisions — for safety, comfort, and performance.

So, trust me: what might seem mundane or theoretical in class turns into tomorrow’s solutions — right there, in the heart of engineering. The bridge from learning to doing is far shorter than it seems. Embrace every STEM lesson; you’re preparing yourself to shape the cars and the safety of the future.

Crash Safety: Physics to the Rescue

Every car crash is physics in motion. Imagine driving at 60 km/h. Your car may feel light and agile, but in reality, it carries enormous kinetic energy:

For a 1,200 kg car at 60 km/h (≈16.7 m/s), that’s over 1.6 million joules — roughly the energy released by dropping a loaded school bus from a height of 1 meter. All that energy doesn’t disappear in a crash; it must be absorbed and managed by the BIW in milliseconds. If the car were a rigid block of steel, the occupants would feel the entire force instantly. But modern BIW designs use crumple zones — engineered areas that deform in a controlled way, stretching the crash duration and reducing the force on passengers.

The key principle comes from Newton’s laws:

By increasing the crash duration (Δt) through deformation, the average force F experienced by occupants drops dramatically. That’s why the front rails fold like an accordion during a frontal crash — they’re sacrificing themselves, so the people inside don’t have to.

Isaac Newton once remarked, if I have seen further, it is by standing on the shoulders of giants.

In a way, every crashworthy car today is standing on Newton’s shoulders, translating his fundamental equations into the structures that save millions of lives each year.

Different Crash Scenarios

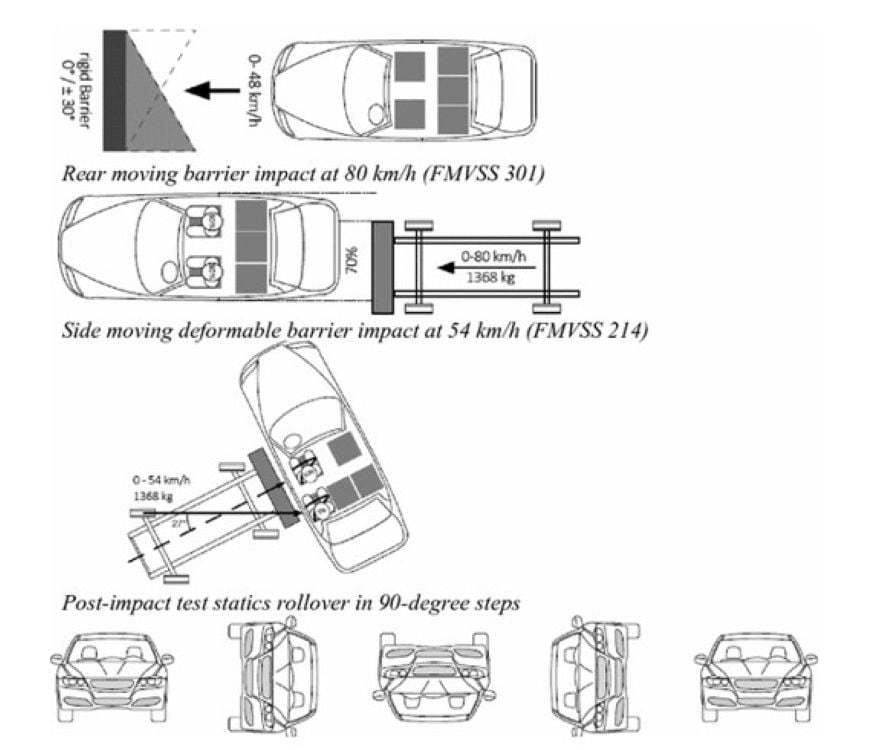

The BIW design must pass several “exams” in safety:

- Frontal Impact: About 60–70% of real-world crashes are frontal. Longitudinal rails, cross members, and the firewall deform to absorb energy.

- Side Pole Crash: Especially lethal—a U.S. total of 46,000 road fatalities in 2022 drives engineering for ultra-strong pillars and door beams.

- Roof Strength: During rollovers, the roof must not collapse, so roof rails and cross-members are reinforced.

- Rear Impact: Especially critical in EVs, where batteries are mounted under the floor or rear seats. Crash boxes at the back manage loads here.

Quick Fact

Volvo pioneered crumple zones in the 1970s with the Volvo 240, proving that safety could be engineered for frontal crashes. Today, Tesla’s Model 3 uses massive aluminum castings to route crash forces around battery packs for side impact.

Mounting Components: The BIW Design as Scaffolding

The BIW isn’t only about safety; it anchors every vital system — engine, suspension, electric motors, batteries — with precision. This demands a delicate balance: mounts must be stiff (to hold parts in place) and yet flexible enough to manage loads and forces.

Engineers use the stress equation to design every bolt and bracket with safety margins:

where F is force and A is cross-sectional area.

A single failure can cascade into catastrophic effects, making this both critical and challenging.

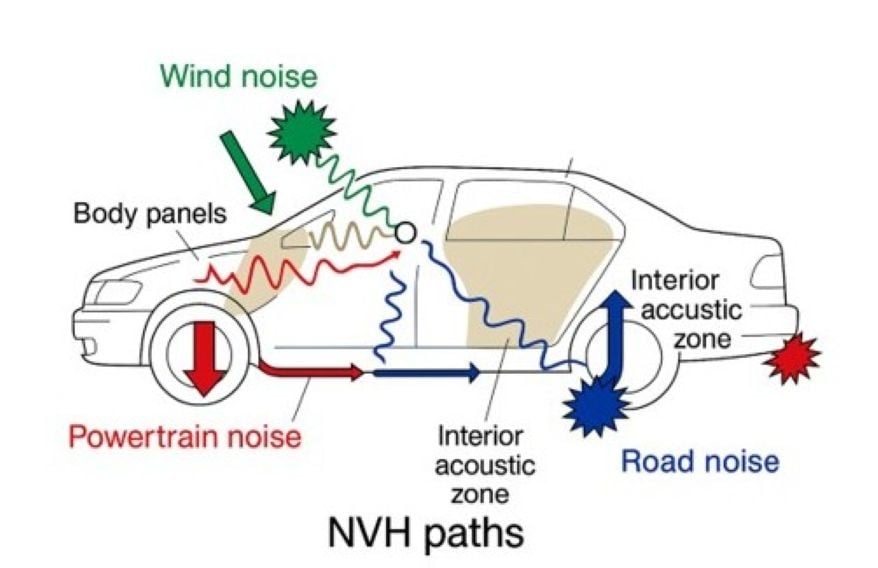

Comfort and NVH: Science Behind a Silent Cabin

After safety, comfort becomes a primary concern. NVH — Noise, Vibration, and Harshness — governs the quality of every ride, turning physics into a tangible experience. While crashworthiness protects life in seconds, NVH defines how occupants feel in the car for hours.

STEM students may remember solving the damped harmonic oscillator in class:

Here, m is the mass, c the damping, k the stiffness, and x the displacement. This humble equation describes everything from the rattle of a loose door to the resonance of an entire car body at highway speed.

A car is, of course, a complex version of this equation, with dozens of modes. For instance, a car roof may vibrate at 30 Hz, while the floor pan resonates at 80 Hz.

When the excitation frequency (from the road, engine, or wind) matches the car body’s natural frequency, resonance occurs. That’s when mirrors shake, dashboards buzz, and passengers complain of bumpy rides. Engineers counteract this by tuning stiffness, adding damping pads, or shifting frequencies out of the sensitive human hearing range (20–200 Hz)

Practical NVH Aspects in Driving:

If your car’s side mirror vibrates at 80 km/h, that’s a resonance. If you hear a booming sound in the cabin at certain speeds, that’s standing waves of air coupling with body vibrastions. The BIW plays a big role here, too. A well-designed structure blocks noise paths, reduces vibrations, and creates a comfortable cabin. In short, good NVH design means the car feels like a calm cocoon. A poor NVH design makes the car feel like a washing machine on spin cycle. In the case of EVs, the cabin is very quiet due to the absence of an engine; in this case, sometimes we may even need to add artificial sounds so drivers don’t lose auditory feedback.

The BIW functions as both filter and amplifier: it channels energy away from critical zones, absorbs unwanted vibrations, and supports damping materials. Engineers carefully tune its stiffness, mass distribution, and connection points to balance rigidity with compliance, ensuring a quiet, comfortable cabin.

BIW Design Rigidity: The Unshakable

As mentioned earlier Rigidity is one of the 4 pillars or core functions of BIW. Rigidity is important in providing the essential structural stiffness that resists bending, twisting, and vibrations throughout a vehicle’s life. In STEM coursework, rigidity relates directly to mechanical and materials engineering concepts such as Young’s modulus and the moment of inertia, which together define how much a structure will deform under load. For example, bending stiffness is calculated using the formula:

EI = Young’s modulus X Moment of Inertia

where E is a measure of material stiffness and I is the resistance to bending based on the cross-sectional geometry.

Similarly, Torsional rigidity, another critical factor, is given by:

GJ = Shear mod X Polar moment of inertia

which predicts how a structure will twist under torque. BIW engineers use these equations to design reinforced pillars, cross-members, and floor panels so that cars stay stable in sharp turns and resist frame-flex during everyday driving. The judicious use of materials and topology optimization ensures that BIWs’ designs are both lightweight and rigid, balancing performance with safety.

From Equations to Experience: The BIW as a Living Lesson in Physics

The Body-in-White is a physics lab on wheels. This is where the STEM curriculum suddenly feels alive. The same impulse–momentum equations you solve in physics class? They decide whether a crash is survivable. The stress–strain curves from materials science? They guide whether a pillar bends or breaks. The harmonic oscillator in math? That’s the difference between a highly smooth luxury ride and a bone-shaking budget car.

And history has proved this connection time and again. The Volvo 240 turned Newton’s physics into safety. Tesla turned vibration control into EV refinement. Each leap shows how classroom equations, when built into steel and aluminum, shape everyday human experiences.

In this article, we walked through how crash energy is absorbed, how vibrations are tamed, and how every ride is shaped by equations you may already know.

Road Ahead: BIW as Career Path

For STEM students considering the future, BIW design engineering offers a dynamic and rewarding career path — with opportunities ranging from structural design and simulation to testing, manufacturing, and quality control. Major automotive companies, EV startups, and suppliers all hire BIW design engineers to create safer, lighter, and smarter vehicles. Specialized roles include design engineers, dimensional analysts, manufacturing process leads, and NVH specialists. With skills learned in STEM courses, students can help shape next-generation mobility and directly contribute to automotive safety and innovation.

Additionally, to stay updated with the latest developments in STEM research, visit ENTECH Online. Basically, this is our digital magazine for science, technology, engineering, and mathematics. Furthermore, at ENTECH Online, you’ll find a wealth of information.