Want to Build Safer Cars? This Engineer’s Story Will Drive You to STEM Education and Career!

Estimated reading time: 17 minutes

Designing and building safer cars is essential today. Recent global crash and accident data shows a concerning picture. The World Health Organization says that more than 1.3 million people die each year in road traffic crashes. This makes it a leading cause of death worldwide. Additionally, 20–50 million people have non-fatal injuries each year. Non-fatal means these injuries do not cause death, but many lead to lifelong disabilities. These shocking numbers show the urgent need to focus on vehicle safety. It is essential for creating a healthier and safer society.

The automotive industry must create and improve cars to keep everyone safer. This includes drivers, passengers, and pedestrians. It is important to make progress in features that protect people during accidents. Structural integrity refers to the strength and durability of a vehicle’s frame. Accident-avoidance technologies help prevent crashes before they happen. By focusing on safety, the industry can save many lives. It also allows people to travel feeling more secure and calm.

Role of STEM Education in Building Safer Cars for Tomorrow

To tackle this urgent challenge, the automotive industry needs a constant supply of young professionals. These professionals should be passionate about STEM subjects. We should encourage teenagers who want to make safer cars. They can explore education in fields like mechanical engineering, automotive engineering, computer science, and materials science. These subjects will give them a strong foundation while still in high school. This foundation will help them design and engineer safer cars in the future. With proper guidance and motivation, today’s young people can make a big difference. They can change the automotive world and create safer and more sustainable transportation for everyone.

To inspire teens for this purpose, we are presenting an educational and professional journey of Lakshmi Prasad Bhatta. He leads “Vehicle Safety” at Mahindra Automotive North America. Here are some excerpts from his candid conversation with founder editor Dr. Charudatta Pathak.

General Background

Can you tell us about your journey into the field of automobile engineering, and what inspired you to pursue this career?

Growing up in a transportation-related family, I became intrigued by vehicle design and occupant safety. I wanted to design faster, safer cars and pursued mechanical engineering. I worked at Mahindra, contributing to the development of safety systems for brands like BMW, Audi, Chrysler, and Jeep. My focus has been on innovations in crash safety, energy absorption, and occupant protection during accidents. As a seasoned expert, I continue to push the boundaries of vehicle safety, combining crash dynamics knowledge with cutting-edge technology to design faster, safer, and environmentally sustainable vehicles.

What are some of the most significant projects you’ve worked on during your 20 years in the industry?

Starting my career at Mahindra, I honed my skills in crash safety while working on the Scorpio SUV, which had a significant impact on safety performance. I have been involved in several groundbreaking projects that have advanced vehicle safety and performance standards. With the rapid increase in demand for electric vehicles, ensuring the protection of high-voltage battery packs from severe impacts, such as side-pole collisions, has become essential to prevent electrical short circuits and thermal runaway. To safeguard the battery pack, I designed and patented a protective energy absorption structure specifically tailored for high-voltage battery packs in electric vehicles.

I recently spoke at the “The Future of Automotive Testing” international conference as a guest speaker. I talked about “Ensuring battery safety in vehicle crash scenarios with due care testing.” This topic is important. It focuses on protecting battery integrity during real-world crash situations.

I previously developed and patented a frontal impact mitigation system at Stellantis, which aimed to lessen the severity of crashes. I also designed a body structure aimed at enhancing crush resistance during rollover incidents. These innovations have significantly impacted the safety ratings of Jeep and RAM vehicles. 2019 RAM 1500 received IIHS Top Safety Pick+, the highest safety award, and NCAP 5-star ratings. 2013 Jeep Cherokee received IIHS Top Safety Pick award and Euro NCAP 5-star ratings.

About a decade ago, I received an award for leading safety development projects. These projects were for Fiat Chrysler Automobiles’ vehicle programs in Latin America. I worked on making design improvements. These improvements greatly boosted safety and performance in vehicles. In these projects, it’s crucial to balance design with real-world testing. This means making sure the vehicles meet safety rules. It also ensures the vehicles keep passengers safe.

Automatic Emergency Braking (AEB)

Early in my career, I studied many vehicle crashes. I started to focus on how to avoid crashes. Around 12 years ago, Chrysler held an Innovation Week. This event encouraged employees to suggest ideas that could give us a competitive advantage. I introduced the idea of Automatic Emergency Braking (AEB). This system automatically applies the brakes if a collision is about to happen. I received formal recognition for this idea. About 20 ideas were chosen for further development in Chrysler Group vehicles. My AEB concept appeared first in the 2017 Chrysler Pacifica. It then expanded to include five more Jeep and Dodge models.

With a proven record of individual contributions and notable achievements as a leader and expert in vehicle crash safety, I became a member of the U.S. Technical Advisory Group for ISO global standardization in the national interest. My goal is to improve public safety through these standards. I review draft standards actively. I also assess the work of others. Furthermore, I make careful decisions when voting on important issues.

Design and Engineering for Safer Cars

What role does creativity play in vehicle concept design, and how do you balance it with engineering principles?

Creativity drives my innovation in vehicle concept design, allowing me to create functional and captivating designs. By balancing creativity with engineering principles, I ensure my imaginative ideas are exciting, feasible, safe, and efficient, helping to solve complex problems.

In crash safety design, creativity is crucial as I reimagine vehicle structures to better absorb crash energy and protect occupants during impacts. My patented frontal impact mitigation system exemplifies this, using creative thinking to reduce collision severity by moving vehicles away from the impact direction, grounded in physics and vehicle dynamics.

I apply engineering principles to implement my creative ideas without compromising safety, performance, or manufacturability. When designing crash structures, I consider material strength, energy absorption properties, and various crash scenarios. I evaluate innovative concepts through physics and material science, testing them with simulations and prototypes.

Balancing occupant safety with vehicle performance is essential in my work, often requiring collaboration between design and engineering disciplines. This process involves finding elegant, efficient solutions that align with safety regulations, aesthetics, and performance, integrating knowledge from crash engineering, materials science, and aerodynamics.

Ultimately, my best designs emerge from meticulous engineering that combines creativity with safety and functionality, ensuring the vehicle performs at its maximum potential.

Can you explain the importance of vehicle testing and validation in the design process for Safer Cars?

Vehicle testing and validation are crucial for ensuring my vehicle’s safety and effectiveness in real-world conditions. I conduct simulations and real-world trials to gather data that simulations alone cannot fully replicate. For instance, during crash testing, I lead the team to perform physical tests to validate the vehicle’s behavior in actual accidents. Tools like LS-Dyna help me identify potential weaknesses in the design before physical testing begins. I also evaluate non-crash factors such as durability, noise, vibration, and harshness (NVH) to ensure smooth and comfortable performance throughout its lifecycle. Validation is important to me, as I ensure that virtual results align with physical test outcomes, taking real-world variables into account. I carefully calculate airbag deployment space to ensure proper functionality during impacts. This iterative process allows me to deliver a reliable and safer car on the road.

How do you set design guidelines to ensure that vehicles meet safety regulations and crash safety requirements?

Setting design guidelines to meet safety regulations and crash requirements is complex but essential in my vehicle engineering work. I analyze safety standards to protect occupants during accidents, establishing targets like structural limits. I also address the unique challenges of electric vehicles by designing an energy absorption structure to minimize battery intrusion. Continuously assessing designs with real-world data and simulations, I ensure compliance with evolving safety standards while enhancing overall performance and safety for occupants.

Technology and tools

You have experience with various engineering tools. How do software applications like LS-Dyna and Ansa enhance vehicle design and analysis?

LS Dyna is like the magician of simulation software, just like other physics-based solvers—it uses advanced physics and mathematics to predict how materials will behave in a crash. It considers everything from material strength to how they fail under high-speed impacts. On the other hand, Ansa serves as a pre-processor, assisting us in building finite element models that feed into LS-Dyna. Together, they streamline the process, helping us design better cars faster while cutting down on development time and costs.

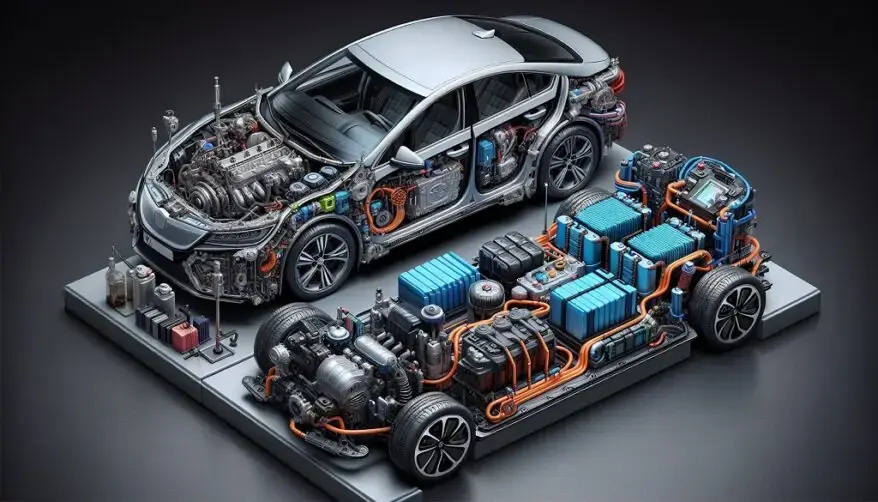

What are the key differences in developing internal combustion engines versus battery electric vehicles?

The difference is night and day! In internal combustion engine (ICE) vehicles, you’ve got fuel, exhaust systems, cylinders, and pistons. In electric vehicles (EVs), you’re dealing with high-voltage battery packs and cables. EVs tend to be heavier, which can pose a significant risk during crashes.

From a crash safety perspective, in ICE vehicles, you have to protect the fuel system to avoid fires. In EVs, it’s all about protecting the batteries from thermal runaway—a fancy term for when they overheat and catch fire. Since highly inflammable materials make up batteries, ensuring their safety during a crash is of utmost importance.

Challenges and Innovations

What are some typical challenges you face in vehicle design and development, and how do you overcome them?

From a crash and safety perspective, one of the most difficult challenges is dealing with variations in material behavior. Even small differences in the forming process or assembly can change how a car behaves in a crash. Test-to-test variations also occur due to the non-linear behavior of materials, inconsistent sensor signals, and equipment.

To overcome these, we build a margin of safety—typically 10–20% above the target performance for some sensitive test cases—in our virtual simulations. This gives us some breathing room when dealing with real-world variations.

How do you see the role of autonomous driving features evolving in the automotive industry?

Autonomous driving is changing the way cars work, making them smarter every day! In the future, cars will take over more driving tasks, like steering and braking. Currently, there are features like automatic emergency braking (AEB), lane-keeping, and adaptive cruise control that help make driving safer. About 12 years ago, I implemented my idea for AEB in the Jeep program. It helps the car stop automatically if it detects a collision coming. It was one of the early steps toward making cars smarter and safer.

In the future, cars will be able to drive themselves without any help from a human driver! They’ll use artificial intelligence, sensors, and machine learning to figure out how to drive in all situations. This will not only make driving safer, but it will also reduce traffic accidents caused by human mistakes. As these technologies get better, we’ll have cleaner, safer roads and more efficient transportation, which could change how cities work and help reduce pollution. It’s an exciting future where cars might just do everything for us!

Teamwork and leadership

As someone with excellent project management skills, how do you keep your team motivated and aligned with common goals?

The key to a successful team is communication, trust, and recognition! Whether I’m leading a project to design a safer car or creating new electric vehicle technology, I always start by making sure everyone knows what we’re working on and why it matters. This way, everyone is on the same page.

I also let my team members lead in different parts of the project, giving them the freedom to explore creative solutions. That’s when the best ideas come out; everyone feels proud of their work. This kind of teamwork has led to some of the safest, most innovative cars on the road today!

Lastly, recognition is key to maintaining morale and motivation. Throughout my career, I’ve made it a point to celebrate every achievement, regardless of its size. Recognizing hard work fosters a positive and productive atmosphere. For instance, FCA awarded me for leading the LATAM programs and managing safety design improvements, which directly contributed to achieving higher vehicle safety standards.

Can you share an example of a complex task you managed and how you approached it with your team?

One of the hardest projects I worked on was making sure electric vehicle batteries stay safe in crashes. We needed to prevent the battery from catching fire during side impacts, which is a big challenge. To solve this, I broke the task into small steps. We first studied how the battery would react in different crash situations using simulations.

Then, I brought together a team of experts in materials, crash safety, and electrical systems. Together, we designed a new protection system that included energy-absorbing materials to stop the battery from breaking. After testing our designs through both computer models and physical crash tests, we found a solution that kept the battery safe even in the toughest crashes. This collaboration and careful planning helped us improve electric car safety!

Data analysis and future trends

How important is data analysis in the development of vehicles, and what kind of data do you typically focus on?

Data plays a crucial role in my car design process, guiding my decisions before any physical builds. I focus on data from crash simulations, handling tests, and various forces to ensure passenger safety during collisions. I also analyze data from sensors and cameras for advanced driving features like lane assistance and automatic braking. As cars become smarter, I use more data to predict maintenance needs and traffic behavior. Ultimately, leveraging data allows me to design safer, more efficient, and reliable vehicles that meet global standards.

What upcoming trends in automobile engineering excite you the most, particularly regarding sustainability?

One of the most exciting trends I see is the rapid evolution of energy storage and propulsion systems, including solid-state batteries and hydrogen fuel cells, which promise longer driving ranges and cleaner energy for carbon-neutral transportation. The advancements in autonomous technologies and advanced driver assistance systems (ADAS) that improve safety and fuel efficiency also fascinate me. The emergence of vehicle-to-everything (V2X) communication aims to create smarter traffic systems, reducing congestion and emissions. Additionally, the push for lighter, recyclable materials in vehicle design addresses environmental concerns. Innovations in energy, materials, and smart technology are driving the future of automobile engineering, resulting in cleaner and more sustainable transportation.

Advice for Teens

What advice would you give to teens interested in pursuing a career in STEM, particularly in the field of automobile engineering?

First and foremost, I embrace curiosity in automobile engineering, constantly asking “why” and “how” to foster innovation and problem-solving. A strong grasp of mathematics and physics is essential, as these core subjects help me think critically and tackle problems creatively. I also prioritize hands-on learning, whether it’s tinkering with car parts or experimenting with electronics. Staying updated on trends like electric vehicles and automation gives me an edge in the field. Perseverance is crucial, and I find satisfaction in overcoming challenges, collaborating with others, and continuously learning. Now is the perfect time to dive in, as the future of automobiles focuses on sustainability and cutting-edge technology.

Are there any specific skills or experiences that you believe are essential for young engineers entering this field?

As I embark on my journey in automobile engineering, I understand that building a solid foundation in physics, mathematics, and materials science is critical. Grasping the interactions of forces, motion, and energy helps me manage complex systems effectively. I value hands-on experience, applying classroom knowledge through internships and projects to solve real-world challenges.

Being adaptable is essential in this fast-changing industry, so I make it a priority to stay updated on technologies like electric vehicles and autonomous systems. I also recognize the growing significance of coding and data analysis skills in developing smart vehicles. Lastly, I know that strong problem-solving and teamwork abilities are crucial; effective collaboration and clear communication are just as important as my technical skills. This blend of knowledge and soft skills will pave the way for my success in the field.

Closing Thoughts

How do you envision the future of automobile engineering in the next decade?

In the next decade, I’m excited to witness incredible changes in car technology! I envision cars that drive themselves, avoid accidents, and communicate with each other to prevent traffic jams. Electric vehicles will become incredibly common, with faster charging eliminating long wait times. We’ll also see cars constructed from lightweight, recyclable materials, making the industry more eco-friendly.

Additionally, cars will become smarter, featuring personalized recommendations, smart navigation, and the ability to anticipate my needs. We are focusing on creating safer, greener, and more connected vehicles than ever before in the future!

What hobbies or activities outside of work do you believe complement your skills as an engineer?

Outside of work, I love working on DIY projects. Whether fixing things around the house or designing solutions for everyday problems, this hands-on work keeps my engineering mindset sharp. I also enjoy biking, which gives me time to clear my mind and come up with new ideas for my projects.

I’m always reading about the latest tech trends, too, especially in AI and electric vehicles. Staying updated on new technologies inspires the innovations I bring to my work, like safety improvements for Mahindra vehicles. These hobbies help me stay creative and continue embracing innovative approaches in my professional life.

To stay updated with the latest developments in STEM research, visit ENTECH Online. This is our digital magazine for science, technology, engineering, and mathematics.

At ENTECH Online, you’ll find a wealth of information. We offer insights and resources to fuel your curiosity. Our goal is to inspire your passion for new scientific discoveries.

Disclaimer: This article/blog post is not intended to provide professional or technical or medical advice. Please consult a healthcare professional before making any changes to your diet or lifestyle. AI-generated images are used only for illustration and decoration. Their accuracy, quality, and appropriateness can differ. Users should avoid making decisions or assumptions based only on the text and images.

See also

Disclaimer: This article/blog post is not intended to provide professional or technical or medical advice. Please consult a healthcare professional before making any changes to your diet or lifestyle. AI-generated images are used only for illustration and decoration. Their accuracy, quality, and appropriateness can differ. Users should avoid making decisions or assumptions based only on the text and images.