The Step-by-Step Process of Making Toughened Glass

Toughened glass is a safety glass made stronger through heat treatment. It is very important in construction, cars, and electronics. Also, this glass can handle strong impacts and big temperature changes, making it very useful today. By learning how it’s made, you’ll understand why toughened glass is so important for safety and new ideas.

What Is Toughened Glass?

Definition and Characteristics

Toughened glass, also called tempered glass, is a strong safety glass. It goes through a special heating process to make it tougher than normal glass. Specifically, this glass can handle impacts, high heat, and pressure without breaking easily. In fact, if it does break, it crumbles into small, dull pieces instead of sharp ones, lowering the chance of injury. Here are some main features of toughened glass:

| Property/Characteristic | Description |

|---|---|

| Enhanced Strength | Stronger and harder to break than normal glass. |

| Safety | Breaks into tiny, safe pieces, great for safety uses. |

| Thermal Resistance | Handles high heat, perfect for ovens and car windows. |

| Durability | Lasts longer and resists damage better than regular glass. |

| Versatility | Used in buildings, cars, and electronics. |

| Optical Clarity | Stays clear like regular glass. |

| Easy Maintenance | Simple to clean and doesn’t stain easily, good for kitchens and baths. |

How Toughened Glass Differs from Regular Glass

Toughened glass is very different from regular glass, also known as float glass. Indeed, the way it’s made is the biggest difference. Manufacturers heat float glass to about 600-650°C and then cool it quickly with air. Actually, this process, called quenching, makes the surface stronger. It becomes five times tougher than regular glass.

Common Uses of Tempered Glass

Many industries use tempered glass because it is strong, safe, and flexible. Some common uses are:

- Automotive: Found in car windows for safety and heat resistance.

- Construction: Used in building walls, doors, and room dividers.

- Residential: Found in shower doors, tables, and glass shelves.

- Foodservice: Great for restaurant ovens and kitchens due to heat resistance.

Its mix of strength, safety, and good looks makes it a key material today.

The Manufacturing Process of Toughened Glass

Cutting and Shaping the Glass

The first step in making toughened glass is cutting and shaping. Sheets of float glass are chosen for their strength and quality. Particularly, machines cut the glass to the needed size and shape. Additionally, these machines make sure the edges are smooth and the size is exact.

Sometimes, extra steps like polishing or drilling are done. For example, shower door glass may need smooth edges for safety. Also, this step gets the glass ready for the toughening process while keeping it strong.

Cleaning and Preparing the Glass

Before heating, the glass must be cleaned well. Cleaning follows strict rules to keep quality high. These rules are updated to match industry standards. Clean glass not only looks better but also lowers the chance of breaking during the toughening process. Dirt or dust can ruin the tempering process and cause flaws. Particularly, special cleaning tools remove all dirt and make the glass spotless. This ensures the glass is ready for heating.

Heating the Glass in a Furnace

After cleaning, the glass is heated in a furnace. The furnace heats the glass to 570°C–620°C (1058°F–1148°F). This softens the glass so it can be cooled quickly.

The furnace temperature is carefully checked to avoid overheating. In fact, overheating can cause the glass to warp. This step is very important because it prepares the glass for cooling. Proper heating makes the glass strong and keeps it clear and smooth.

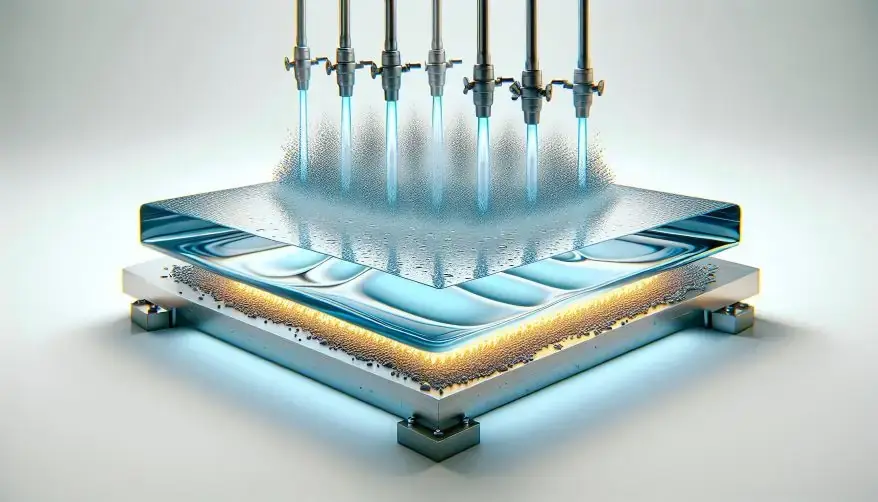

The Quenching Process

The quenching process is an important part of making toughened glass. After heating, the glass is cooled quickly with strong air pressure. Additionally, this fast cooling makes the outer layer compress while the inside stays tense. Also, this special structure gives the glass its strength and safety.

There are different ways to do quenching:

- Conveyorized quenching: Air blows on the glass as it moves on a conveyor.

- Oscillating quenching: The glass moves back and forth for even cooling.

- High-volume air systems: These are used for either large or small production needs.

Quenching increases the glass’s ability to hold weight. Cooling must be even to avoid problems. Air nozzles help with this, but uneven cooling can happen. Tiny cracks might form, which can weaken the glass.

This step is key in the heat treatment process. It decides how strong and safe the glass will be. Good quenching makes the glass tough and ready for many uses.

Inspection and Quality Assurance

After quenching, the glass is carefully checked to meet standards. Quality checks make sure the glass is strong, safe, and long-lasting. Different tests are done to check the glass. Visual checks look for scratches or flaws. Air and water tests ensure it can handle weather. Wind tests confirm it stays stable in storms.

These checks make sure the glass is safe and works well. By following strict rules, makers ensure the glass is dependable for many industries.

Machinery Used in the Manufacturing Process

Glass Cutting Machines

Making toughened glass starts with cutting it precisely. Modern glass cutting machines use smart technology for accurate results. CNC (Computer Numerical Control) machines are common for this task. They cut glass into complex shapes with ease and handle different thicknesses. This makes them useful for many purposes.

Here’s what these machines can do:

| Specification | Details |

|---|---|

| Precision and Quality | Cuts glass cleanly and with high accuracy. |

| Speed and Efficiency | Works faster than hand-cutting, great for big projects. |

| Versatility | Can cut various glass types and thicknesses. |

| Cost-Effectiveness | Saves material and keeps quality consistent. |

These machines also reduce waste, helping the environment. Smooth edges from these machines reduce the amount of extra work needed. This saves both time and materials.

Heating Furnaces for Tempered Glass

After cutting, the glass goes into a tempering oven to heat up. These ovens warm the glass to over 600°C, making it soft for the next step. Advanced furnaces have tools to measure glass temperature and monitor heat levels. This ensures the glass stays strong and clear.

Key furnace features include:

- Cycle Time Optimization: Adjusts heating times to save energy.

- Thermal Barrier Design: Spreads heat evenly to avoid warping.

- Real-Time Data Display: Tracks temperatures for better quality control.

Controlling the heat carefully stops the glass from bending. This step is crucial for making strong float glass that meets industry needs.

Quenching Systems and Their Role

The quenching process is where the glass becomes tough. After heating, high-pressure air cools the glass quickly. This creates a strong outer layer and a tense inner layer, making the glass very durable.

Modern quenching systems offer these benefits:

- Enhanced Precision Cooling: Keeps the glass flat and reduces rainbow-like effects.

- Gas Quenching: Cools evenly, avoiding size differences.

- Safety and Efficiency: Gas cooling is safer and better for the environment than liquid cooling.

These systems work for both small and large production. Even cooling stops cracks or bends, making the glass strong and ready for many uses.

Inspection Tools and Equipment

Inspection tools are important for checking toughened glass quality. They make sure the glass is safe and meets standards. Advanced methods help manufacturers create reliable glass for many uses.

Visual inspections are often used to find surface problems. These checks look for scratches, cracks, or alignment issues. This step ensures the glass looks good and works properly. Air and water tests check if the glass can handle wind and rain. These tests show how the glass performs in real conditions.

Good equipment is key for inspections. Automated scanners find tiny flaws in the glass. Regular tool maintenance keeps results accurate and reduces delays. Clear instructions also improve inspection accuracy.

Quality checks confirm the glass meets required specifications. Checklists help assess if the glass follows standards. The AQL sampling method (ISO 2859-1) decides acceptable defect levels in batches. These practices ensure the glass is strong, safe, and ready to use.

Tip: Use calibrated tools and follow updated rules for better inspections.

Properties and Benefits of Toughened Glass

Enhanced Strength and Durability

Toughened glass is much stronger than regular glass. It can handle heavy impacts without bending or breaking. Additionally, this makes it reliable for tough conditions like strong winds or vibrations. In construction, it stays intact even under pressure. In fact, its long-lasting nature means fewer replacements are needed.

The heating and quick cooling process gives it a tough outer layer. Also, this layer helps the glass endure stress and stay strong. Whether used in tall buildings or home furniture, it performs well over time.

Safety Features of Tempered Glass

Safety is a key benefit of tempered glass. When it breaks, it forms small, dull pieces instead of sharp ones. Secondly, this lowers the risk of injuries, making it safer for schools, hospitals, and cars.

It also resists sudden impacts, adding to its safety. For example, in car crashes, it protects passengers from harm. Particularly, its ability to stay strong under pressure makes it ideal for risky environments.

Thermal and Environmental Resistance

Toughened glass handles big temperature changes easily. It works well in ovens and car windows because it resists thermal shock. Even in extreme heat or cold, it stays stable and reliable.

This glass also stands up to harsh weather like UV rays, rain, and wind. Also, it doesn’t stain and stays clear, making it great for kitchens and bathrooms. In fact, these features make it useful for many industries and outdoor spaces.

Versatility in Design and Functionality

Toughened glass is known for its versatility in looks and use. It is used in many areas, from modern buildings to household items. In fact, its mix of strength and style makes it popular in different industries.

Design Flexibility

Toughened glass allows for creative and unique designs. It can be shaped, tinted, or frosted to fit specific needs. For example:

- Tinted glass adds color and cuts glare, great for offices.

- Frosted glass gives privacy but still lets light through, perfect for bathrooms or partitions.

- Curved glass adds style to furniture or car windshields.

You can also add patterns or logos to toughened glass. This makes it useful for decoration or branding.

Tip: Use toughened glass for projects needing both style and strength.

Functional Benefits

Toughened glass is not just strong; it serves many purposes. Secondly, it works well in different settings:

- Energy Efficiency: Special coatings help control indoor temperatures and save energy.

- Noise Reduction: Laminated toughened glass blocks sound, ideal for noisy cities.

- Safety and Security: Its shatter-proof design keeps people safe in risky places like schools.

Why It Matters

Toughened glass is both stylish and practical. Whether for a tall building or a kitchen countertop, it works well. Its flexibility ensures it meets your needs while staying safe and attractive.

Note: Always ask experts to pick the best toughened glass for your project.

Why Toughened Glass Is Essential in Modern Applications

Contribution to Safety Standards

Safety is important, and toughened glass helps a lot. It breaks into small, dull pieces, not sharp ones. Indeed, this lowers the chance of injuries. That’s why it’s used in schools, hospitals, and public places. In cars, it keeps passengers safer during accidents. Many building rules require it for risky areas like doors, windows, and stairs. Its strength and shatter-proof design meet strict safety rules. This makes it a trusted material for today’s needs.

Economic and Environmental Advantages

Tempered glass saves money and helps the planet. It lasts a long time, so you replace it less often. This saves you money over the years. In fact, coated glass keeps rooms cooler or warmer, cutting energy costs. Its long life means less waste, which is good for the environment. In fact, many companies recycle it, reducing the need for new materials. Choosing this glass helps the Earth and your budget.

Role in Everyday Life and Industries

You see toughened glass everywhere in daily life. It is in car windows, phone screens, and kitchen tools. Furthermore, architects use it for beautiful buildings and interiors. Moreover, its strength and clear look fit modern designs well. In factories, it supports heavy machines safely. Additionally, its flexibility makes it useful for many things, from protecting people in cars to improving home and office designs.

Closing Remarks

Making toughened glass requires careful steps like cutting, cleaning, heating, cooling, and checking. These steps make the glass strong and safe to use. Its special features, like resisting impacts and handling heat, make it perfect for many uses. You’ll find tempered glass in buildings, cars, and homes because it’s tough and flexible. Picking this glass means choosing safety, lasting strength, and stylish designs.

References

Datsiou, K. C., & Overend, M. (2017). The strength of aged glass. Glass Structures & Engineering, 2(2), 105-120. https://doi.org/10.1007/s40940-017-0045-6

Cui, Y., Lam, N., Shi, S., Lu, G., Gad, E., & Zhang, L. (2023). Flexural strains in a toughened glass panel generated by impact of an ice sphere. International Journal of Solids and Structures, 281, 112438. https://doi.org/10.1016/j.ijsolstr.2023.112438

Kinsella, D.T., Persson, K. A numerical method for analysis of fracture statistics of glass and simulations of a double ring bending test. Glass Struct Eng 3, 139–152 (2018). https://doi.org/10.1007/s40940-018-0063-z