Stress and Strain: Concepts, Examples, and the Stress-Strain Curve

Estimated reading time: 11 minutes

The field of mechanics that studies how things react to forces looks at stress and strain. Because of this, it is a basic idea in engineering and material science. In particular, strain is a unitless way to measure how much things change shape when they are under stress. So, stress and strain are very important when making things that are safe and work well. Forces are what cause stress, and strain is what causes stress. Because of this, engineers rely on these ideas to keep things from breaking, make them work better. And eventually progress in material science.

Defining Stress in Materials

What is Stress?

Stress happens when an outside force spreads out the material’s internal forces. There are two main types of stress: tensile stress and compressive stress. In math terms, it is described as force per unit area, written as

![]()

which relates to normal stress in material science. Stress explains how materials respond to forces and how these forces are distributed within the material.

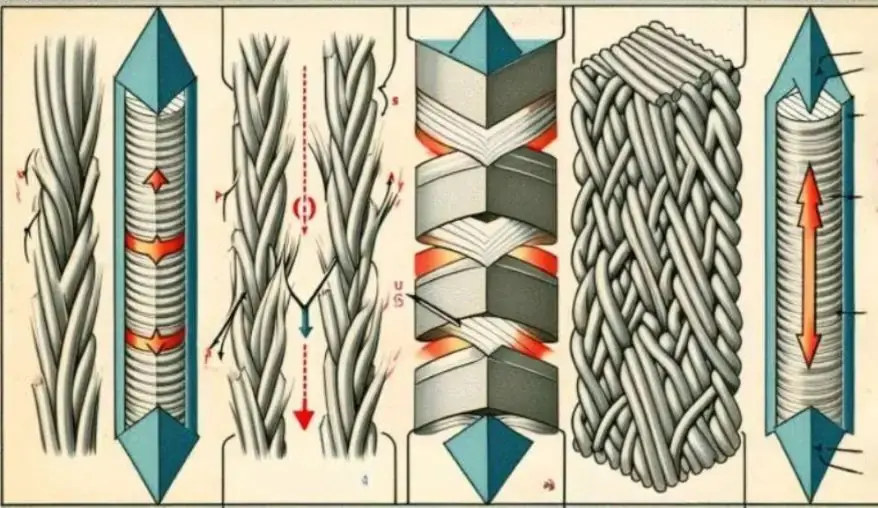

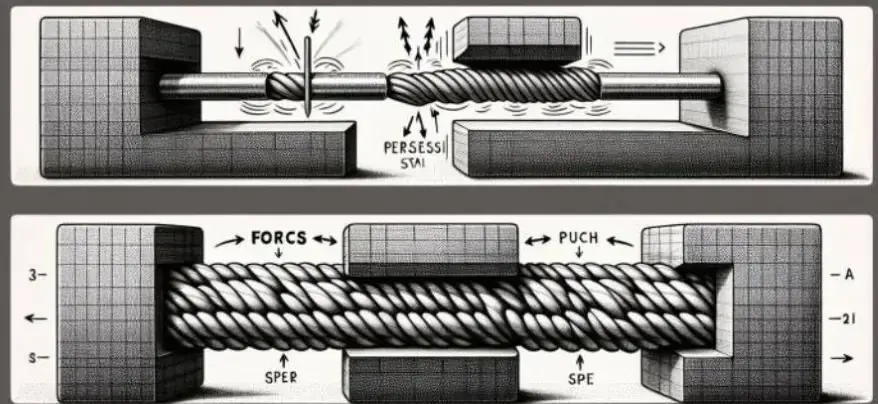

Tensile, Compressive, and Shear Stress

Different situations result in different types of stress:

- An object experiences tensile stress when forces stretch and pull it apart, illustrating the connection between stress and strain. Imagine pulling on an elastic band; this is an example of tensile stress.

- Compressive Stress: This type of stress works the opposite way of tensile stress. Pressing down on the object to show how the deforming force can cause strain. One easy example is sitting on a wooden stool. When you do this, your weight puts compressive stress on the legs of the stool. Because of this, the stool changes shape, showing how different forces can change things in different ways.

- When forces act parallel to the surface, they cause parts of the material to slide over one another. This phenomenon is known as shear stress. It is easy to see how shear stress works when you cut a piece of paper with scissors.

Real-World Implications

Stress is a normal part of life and can be quite loud. Engineers have to think about both regular stress and the material’s ultimate strength when they build suspension bridges. The lines are very tight because they hold up the deck. Columns, especially those in towers, are put under compression stress by the weight of the building above them. Every part, from buildings to simple tools, needs to be analyzed for stress by engineers. This is done to make sure they work well and last a long time.

Exploring the Concept of Strain

Understanding Strain

Strain measures how much an object deforms under a force. Expressed as the ratio of the change in length to the original length:

![]()

Stress addresses the forces applied to a material. Strain provides insight into how much a material changes shape or form in response.

Types of Strain

Strain can manifest in different ways:

- Tensile strain: Normal strain is the ratio of the changed length to the original length. Tensile strain is the lengthening of a stretched material. Moreover, it shows how a material changes shape when pulled. Also, it can be seen clearly when you stretch a rubber band. So, this simple action shows how important strain is for understanding how things behave when they are under stress.

- Compressive stress shortens a material, causing compressive strain. When you push on both ends of a sponge, it gets shorter and more compressed. This shows compression strain and volumetric strain.

- To understand how stress affects things, you need to know about shear strain. It shows how the inside changes when layers slide past each other. Shear strain is like moving the top layer of a deck of cards relative to the bottom layer.

Everyday Examples of Strain

Strain is all around us. When you stretch a spring, tie a knot in a rope. Or even when you bend a thin metal rod, you witness strain in action. These everyday actions showcase how objects adapt to applied forces by changing shape or volume.

Material Deformation and Elasticity in Stress and Strain

How Materials Respond to Stress

Different things behave in different ways when they are stressed. Some of them might be flexible, which means they can go back to their original shape, or plastic. That is, they change shape all the time. In the fields of engineering and material science, this difference is very important. It’s also important to know the difference, especially when looking at pressure vs. stress. Because it helps them figure out how things will behave in various settings.

Elastic vs. Plastic Deformation

When the force is taken away, things that are stretched elastically go back to their original shape. Like, when you stretch a rubber band, it snaps back into shape. Material that changes shape plastically, on the other hand, can’t return to its original shape. This is like how breaking a paperclip outside of its original shape changes it forever. So, engineers need to know about these qualities to make things that can either withstand force or show when they are about to break.

Hooke’s Law Explained

Hooke’s Law is a cornerstone principle, forming the basis of elasticity. It states that stress is directly proportional to strain within the elastic limit of a material. Represented as

![]()

Where E, or Young’s modulus, shows how stiff a material is. Scientists describe it as the ratio of stress to strain and use it to gain important information about how things behave. Because of this, engineers can guess how materials will react to different types of stress if they understand this link. To make structures that can withstand certain pressure, it is important to know the material’s Young’s modulus.

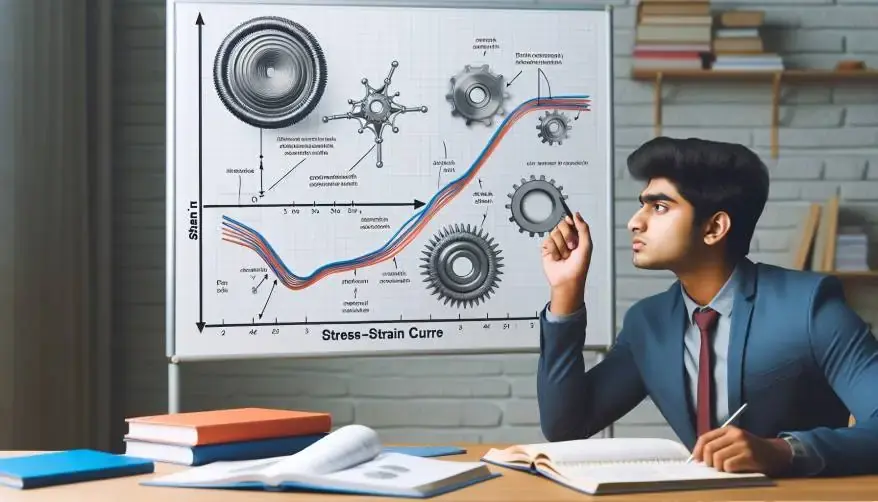

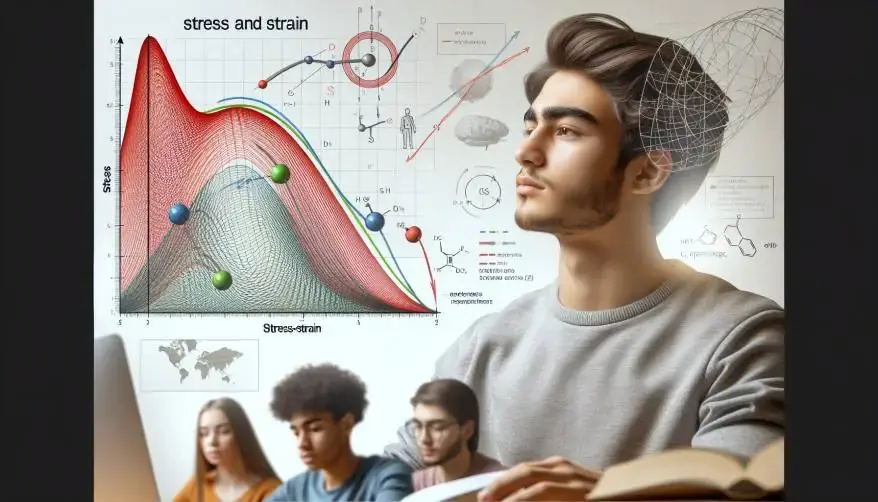

Analyzing the Stress-Strain Curve

Key Regions of the Curve

A strain graph can show how stress and strain are connected in materials. Until the material breaks, the strain curve will show that stress is equal to strain. It’s a graph that displays how a substance responds to various stress levels. The proportional limit shows the areas where this law is valid.

Elastic Limit: Past this point, warping lasts forever.

The Yield Point is an important part of knowing how materials act when they are under normal strain. At this point, the material deforms permanently, which means it might change the structure.

Ultimate Tensile Strength is a key factor in figuring out how well different materials handle stress. This occurs particularly when they are loaded in a single direction. The most stress that a substance can take before it breaks.

Fracture Point: The place where the material breaks, where it snaps or cracks.

Significance in Material Science

By knowing the details of the stress-strain curve, engineers and manufacturers can find problems and stop them before they happen. This helps them figure out what safe materials can do and make shapes that are safer. A lot of the time, knowing a lot about this shape is necessary to make a useful material model.

Influences on Stress and Strain Behavior

Material Properties in Stress

The way that materials react to stress and strain is based on their properties, like Young’s modulus and Poisson’s ratio. Because of these qualities, engineers can pick materials that are right for certain jobs, making sure they are safe and effective.

Environmental and Load Factors in Stress

Besides the qualities that are already there, outside factors have a big effect on how stress and strain move. Changes in a material’s stress can cause different kinds of strain, which can affect how well it works generally. Temperature can greatly affect a material’s final strength. Temperature, along with the type and duration of applied loads, changes the way a material behaves in unique ways. By looking at these things, you can be sure that materials will work as they should in a range of settings and situations, especially when they are under different levels of stress.

Real-Life Engineering Applications of Stress and Strain

Impact on Construction

In the building business, knowing the stress state of materials is very important for making sure that structures are safe and last a long time. So, engineers carefully look at how bridges and tall buildings are built so that they can resist normal stress and, in turn, nature’s forces. This careful examination is necessary to make sure that these buildings stay stable and strong in a variety of situations.

Applications in Automotive and Aerospace

The world of automobiles and aircraft engineering rests on the marriage of weight efficiency and material strength. Examining stress and strain enables the development of vehicles that not only perform rigorously but also maintain safety for passengers.

“Automotive” and “aerospace” are fields where

- material resilience ensures safety in car crashes,

- Performance in aircraft structures supports the formidable pressures and temperature variations, emphasizing the role of elastic modulus in maintaining structural integrity under uniaxial stress.

Biomedical Relevance

In the field of biomedicine, researchers use stress and strain to guide studies and practices related to the human body. For example, knowing how bone works is important because it has special properties that let it handle stress from different kinds of physical activities. As a result of understanding how stress in these materials causes strain, doctors can come up with better supportive or replacement treatments, make medical implants that last longer, and help patients get better.

Core Ideas Recap

Stress and strain are important ideas in a lot of science and engineering. They show us how forces work and give us useful information in this way. These ideas can also be used as models in many fields, from building to biomedicine, to make things better and move things forward.

The Future of Material Analysis

In many cases in the future, materials will work better because we will know more about longitudinal stress. Material analysis can also give you new ideas and information, like how to make new materials that can last in harsh circumstances. They have to handle the stress of their jobs while making cutting-edge monitoring tools. We can now better understand the materials we already have thanks to this molecular-level study. It also lets us make new alloys and composites that could change many businesses.

FAQ’s

Q: How do engineers approach the design of bridges and high-rise buildings?

A: Engineers pay close attention to how big buildings and bridges are put together to make sure they can stand up to normal stresses and natural disasters. This means thinking about things like the properties of the material, how much weight it can hold, and how the environment might affect it.

Q: What role does normal stress play in material design?

A: When we create materials, normal stress is important because it tells us how they will react to forces that are put on them in a certain way. When engineers learn about normal stress, they can make sure that building materials can stand up to outside forces without weakening the structure.

Q: How do engineers ensure that structures like bridges and high-rise buildings remain resilient?

A: Engineers make sure that structures are strong by carefully studying how stresses are distributed in materials and taking into account forces like wind, weight, and other external effects. This helps architects make buildings that can stand up to nature’s forces and keep working properly for a long time.

References

- Jiang, X., Guo, J., Yang, H., Bao, S., Wen, C., & Chen, J. (2023). Study on Stress–Strain Relationship of Coir Fiber-Reinforced Red Clay Based on Duncan–Chang Model. Applied Sciences, 13(1), 556. https://doi.org/10.3390/app13010556

- Jung, H., Oyinloye, T. M., & Yoon, W. B. (2022). Stress and Strain Characteristics under the Large Deformation of Surimi Gel during Penetration and Extension Tests Using Digital Image Correlation and the Numerical Simulation Method. Gels, 8(11), 740. https://doi.org/10.3390/gels8110740

- Sandström, R. (2024). Stress Strain Curves. In: Basic Modeling and Theory of Creep of Metallic Materials. Springer Series in Materials Science, vol 339. Springer, Cham. https://doi.org/10.1007/978-3-031-49507-6_3

- Shan, Y., Zhen, M., & Fill, H. D. (2025). Research on Structural Mechanics Stress and Strain Prediction Models Combining Multi-Sensor Image Fusion and Deep Learning. Applied Sciences, 15(7), 4067. https://doi.org/10.3390/app15074067

Additionally, to stay updated with the latest developments in STEM research, visit ENTECH Online. Basically, this is our digital magazine for science, technology, engineering, and mathematics. Furthermore, at ENTECH Online, you’ll find a wealth of information.