HOW IT IS MADE : The Lead Battery Part V

In lead battery manufacturing, the grids must be coated with the right amount of active material for the plates to function properly. Consequently, the active material enables the battery to store and release energy efficiently. To ensure the proper preparation of the active material mixture, you need the following elements:

- lead oxide

- Manufacturers add materials during production of Lead Battery. There are different types of additives

- water

- sulphuric acid

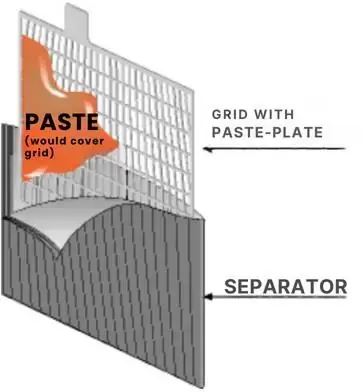

To get the final result, feed these materials in the order mentioned. This follows the heat cycle from sulphating the materials. This process creates a mix with the correct composition and density. First, the mix surrounds the lead battery grids before it turns solid. As a result, this process forms strong compounds with low electrical resistance. These compounds then become the plate components, which consist of the grid and active material. Next, they soak up the electrolyte, a liquid mixture of water and sulphuric acid. Finally, this occurs before the charging phase begins.

Next, they mix the ingredients to create the paste. Following this, they absorb the electrolyte, which is a liquid containing sulphuric acid.

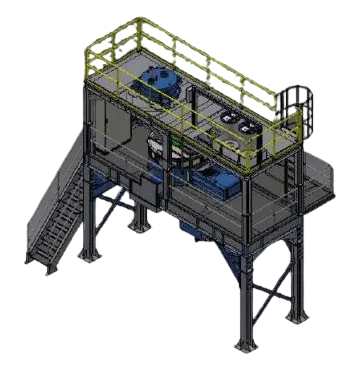

Blade type mixer: groups and operation

The machine in lead battery consists of:

- mixing system;

- mixing tank;

- cooling system.

Mixing Tank

This container holds the mixture components and actively mixes them during the exothermic reaction. This reaction occurs primarily due to lead oxide sulphation. Moreover, to ensure the temperature remains under control, cooling water continuously flows along the bottom and sides of the tank.

Mixing system in Lead Battery

The tank’s central axis spins and operates this system. It has three arms (blades) attached to its outer part. These arms are essential for mixing the mentioned components. One arm cleans the mixer’s side wall. The other two arms stir the material. They move it in two directions: one arm moves it along the radial axis and the other along the tangential axis.

Cooling system in Lead Battery

This equipment sits on top of the tank cover. It controls how much air moves through by adjusting the amount of liquid additive. This means it determines how much of the liquid mixes with the air. It adjusts the ventilation based on the temperature of the material. The system determines when to add distilled water and also recognizes when to introduce sulphuric acid. Since sulphuric acid is a strong chemical, it plays a crucial role in facilitating certain reactions. On the other hand, distilled water is impurity-free and safe to use. Furthermore, the system carefully measures the need for both substances by relying on specific time cycles. As a result, it ensures optimal performance and efficiency in Lead Battery.

Additionally, to stay updated with the latest developments in STEM research, visit ENTECH Online. Basically, this is our digital magazine for science, technology, engineering, and mathematics. Furthermore, at ENTECH Online, you’ll find a wealth of information.